In the pharmaceutical and biotechnology industries, the integrity of product packaging is paramount. Ensuring that containers, particularly glass vials, are free from leaks is a critical aspect of maintaining the quality and efficacy of pharmaceuticals. Leak detection systems play a pivotal role in this process, providing a reliable means of identifying even the smallest imperfections in vial seals.

Understanding Leak Detection Systems:

Leak detection systems are sophisticated tools designed to identify and locate leaks or defects in packaging, preventing potential issues such as contamination or product degradation. In the context of glass vials, these systems utilize advanced technologies to detect leaks that may compromise the sterility and safety of the contents.

The Process of Leak Detection:

The process of leak detection involves subjecting the vials to various tests designed to reveal potential leaks. Common methods include vacuum decay, pressure decay, and helium leak testing. Vacuum decay involves placing the vials in a vacuum and monitoring pressure changes, while pressure decay tests assess the pressure drop in a sealed chamber. Helium leak testing utilizes the sensitivity of helium detectors to trace any gas leakage.

Benefits of Leak Detection Systems:

- Quality Assurance: The primary benefit of leak detection systems is the assurance of product quality. By identifying and addressing leaks early in the manufacturing process, manufacturers can uphold the integrity of their products, reducing the risk of contamination and ensuring compliance with regulatory standards.

- Cost Savings: Early detection of leaks prevents defective products from reaching the market, averting potential recalls and associated costs. Additionally, it minimizes product wastage, contributing to cost savings in the production process.

- Regulatory Compliance: Leak detection systems are crucial for meeting regulatory requirements in the pharmaceutical industry. Adherence to strict quality control measures is essential to comply with regulations such as Good Manufacturing Practice (GMP) and ensure product safety.

- Enhanced Reputation: Consistently delivering products with uncompromised quality builds trust among consumers and stakeholders. Leak detection systems contribute to a company's reputation for producing reliable and safe pharmaceuticals.

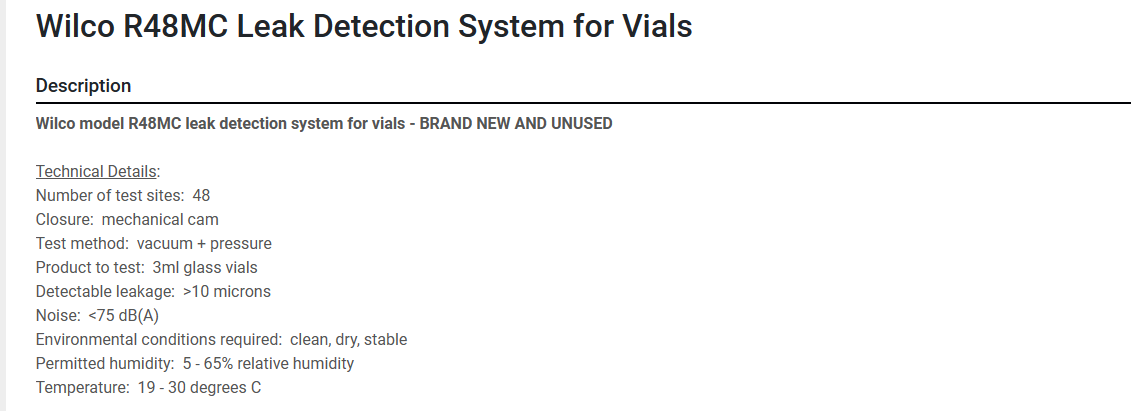

Introducing the Wilco R48MC Leak Detection System for Vials:

Among the cutting-edge solutions available, the Wilco R48MC Leak Detection System stands out as a top-tier option for glass vial integrity assurance. This system utilizes advanced technology to provide unparalleled precision in leak detection. With a focus on vial-specific requirements, the Wilco R48MC is designed to meet the highest standards in the pharmaceutical and biotechnology industries.