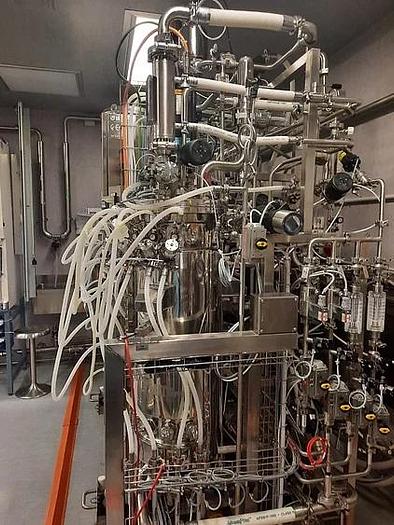

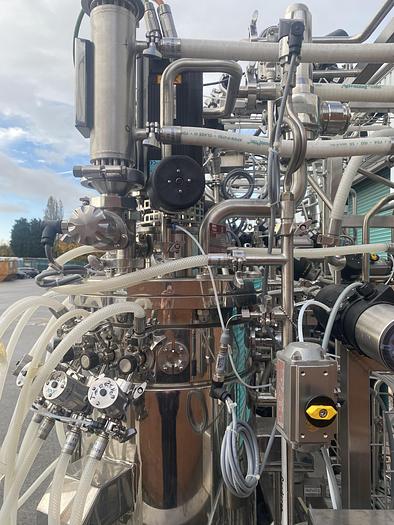

TECNinox Fermenter/Bioreactor

Description

TECNinox Fermenter/Bioreactor suitable for R&D, small batch production, pilot plant

General Description

Fermenter geometry 3:1

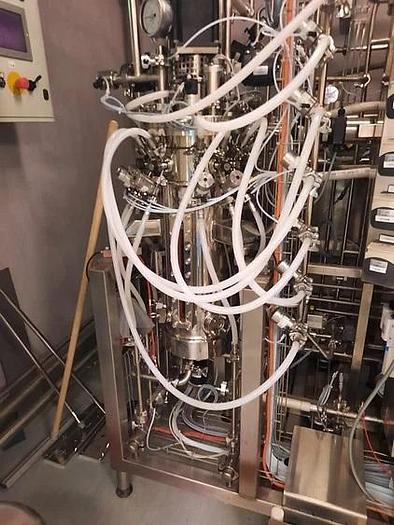

Fermenter head without sharp edges to improve cleaning, GMP gasket

Fermenter head with TC connections of various sizes (3/4, ½, 1), use them for additions, feeding, inoculation, etc.

Working volume for 36L bioreactor: 20L, minimum working volume 7.5L (positioning holder for probes)

Working volume for 74L bioreactor: 50L, dependent on position of last impeller

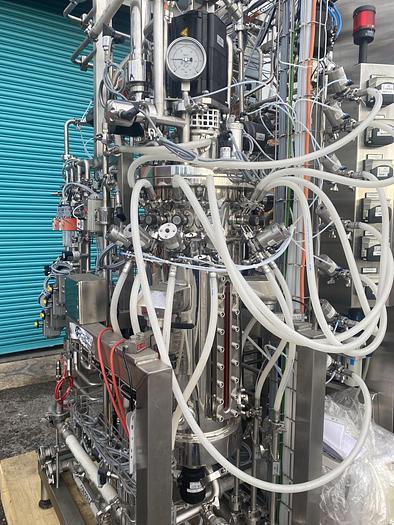

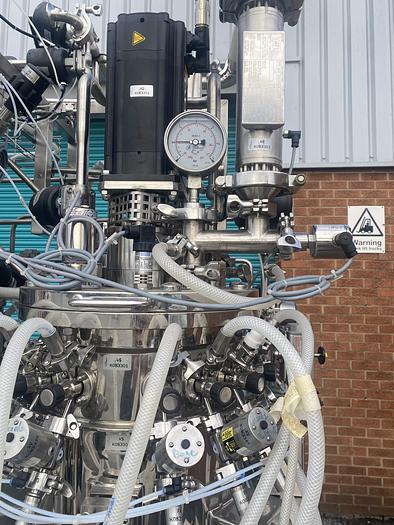

Operational pressure range: -0.01 to 3.00 bar g

Double mechanical seal

Motor position: overhead motor shaft, as close as possible to sparger and bottom

Impellers 3 Rushton / 3 Pitched Blade

Configurable motor speed 50-1500 rpm

Toroidal sparger with possibility of coupling and uncoupling

Exhaust gas condenser

Integrated CIP system

Exhaust gas management: double exhaust gas line after the outlet filter (the gas line must divide into two branches: one direct to the spent gas analysis system (airnova) and the other to the drain/waste)

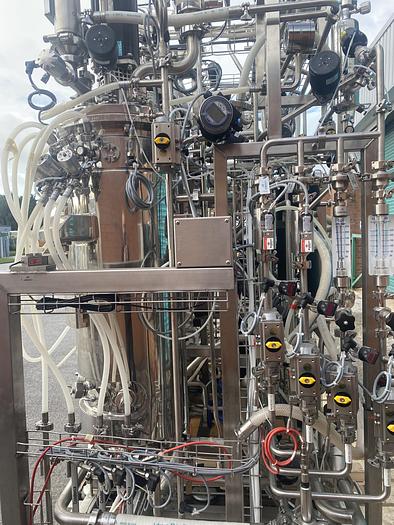

Aeration 0 to 2. 5 VVM

Inlet air from above and from the sparger, with flowmeter

O2 inlet: 0 to 2.5 VVM, O2 inlet from above and from the sparger, with flowmeter

N2 inlet: 0 to 1 VVM, N2 inlet from above and from the sparger, with flowmeter

CO2 inlet 0 to 1 VVM, CO2 inlet from above and from the sparger, with flowmeter

Head pressure adjustment: automatic

Fixed speed pump with remote control

Variable speed pumps, two bottom valves

Bottom valve filter

Integrity test: integrated housing to perform in situ integrity test

Loading soil hole for manual loading

Fixed speed Peristaltic pumping, position adjacent to bioreactor pH, for control of acid/ base, CO2

Feeding base inlet via Sacova valve with ingold control

Utilities needed to run:

Electrical requirements: 380v, 50Hz

Steam feed: 3 - 9 bar

Clean steam: 3 bar g

Purified water

Compressed air 8 bar g

Nitrogen: 8 bar

Refrigerated water: 9 - 12 deg C

Oxygen: 12 bar

CO2: 8 bar

Softened water

Drainage and discharge

This fermenter/bioreactor has two distinct agitation systems, one high shear and one low shear, with different impellor set ups. This allows for high turbidity and low turbidity applications, dependent on the application and organism being grown in the fermentation process.

The unit has the ability to run multiple types of organisms singularly from a minimum fermentation volume of 7.5L to a maximum of 75L however, the unit can run district volumes in between with the break point at 20L 30L giving the operator great flexibility.

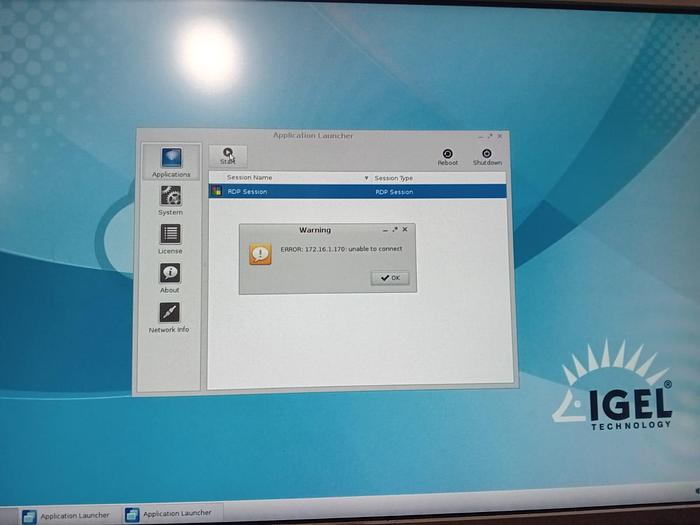

The control software on this machine is TIA Portal which was introduced to the public in 2010 and according to Siemens it will be supported for 22 years and parts will be available for another 5 years after that. SIEMENS TIA is back words compatible. The machine is using a Siemens S7-300 PLC and Ilinox Asem MH215 HMI

Box of manuals included

Condition: AS NEW, UNUSED

Specifications

| Manufacturer | TECNinox |

| Year | 2015 |

| Condition | Used |

| Serial Number | B46-15001 |

| Stock Number | GP10165 |