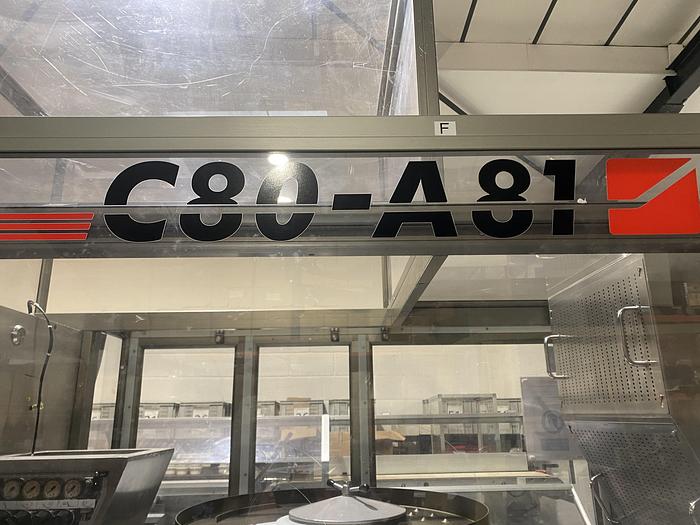

IMA C80/A81 Blister Packaging Line

Description

IMA Blister Packaging Line consisting of model C80 blister packing machine and model A81 cartoning machine

Running hours: 5441

Main Features:

Designed to produce blisters on two or three rows according to the size of the produced blister

Wide blister format size range

Maximum flexibility in layout

Fast and computer guided changeover

Easy to use

Complete accessibility of the material work flow

Easy forming materials loading thanks to the ergonomic position of the reel holder

Automatic blister recovery magazine: ZERO rejection into the cartoner due to missing blisters.

Technical Data:

Production output: up to 400 blisters/min and up to 250 cartons/min

Blister dimensions: width 30-90mm, length 60-150mm, depth/height 3-12mm

Carton dimensions: width 35-93mm, length 70-155mm, depth/height 12-90mm

Current Set Up:

PVC/PP/PET/Polymer base film with thermal forming and ALU lidding foil, twin lane

Forming station measures: 20mm x 11mm x 7mm deep (capsule)

Pack size: 88mm x 52mm, 5 x 2 packs of 10 capsules per pack

Carton size: 100mm x 55mm x 30mm horizontally opposed

Trifold leaflet folder leaflet size: 118mm x 160mm before folding

Will also run ALU/ALU with the correct tooling/format parts

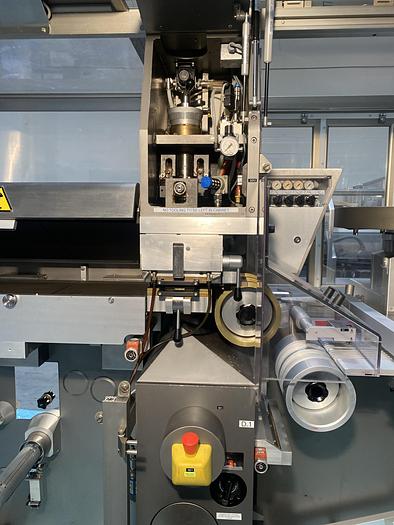

The machine is made up of the following functional areas:

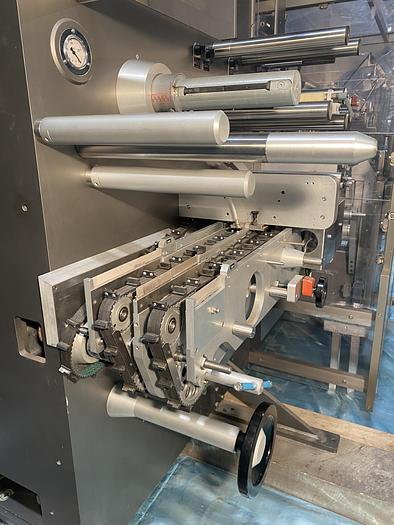

- Forming film reel-holder and unwinder and pocketed film moulding

- Product feeding

- Lidding foil reel-holder and unwinder

- Blister sealing and cutting

- Blister transferral and stack formation

- Cartoning machine

- Leaflet (Option)

- Booklet (Option)

- Motor drives

- Cooling system

- Production check

Working Principle:

The machine moulds the pockets and then fills, seals, cuts and stacks them and lastly packages them inside the cartons.

A special device holds up the reel that contains the forming material which is unwound by a motor driven drive roller.

Then a heating system warms up the film to the required temperature.

If the processed material is the thermoforming type, the pockets are moulded in the warm film by means of a jet of compressed air. Hot pistons are used for certain materials.

When producing aluminium pocketed film, the pockets are moulded in the cold foil by means of a specific moulding system.

The lidding foil is also wound in a reel. The reel-holder is motor driven to guarantee the foil is pulled uninterruptedly as the reel's diameter changes.

A device for centering the print on the lidding foil might be installed.

There are different types of systems for inserting the product into the pockets of the formed film.

The most common one consists in a vibrating bowl paired to a series of down-doing channels.

Other systems included those with trays/buckets or devices made up of one or more pocketed and motor driven rollers.

The check that verifies whether or not the blister was filled is run by a system made up of one or more TV cameras.

The information from the filling check system is processed by the machine's logic that manages the subsequent rejection of any defective packages.

After the filling check has been run, the lidding foil is sealed to the forming film that contains the product.

Then the blister is print-coded and pre-cut at the respective stations.

A pocketed roller, which moves by jogs, inserts the sealed film into the cutting station.

The cut blisters are placed, with the pockets facing up, onto a transferal device that moves by alternating motion.

If producing on two rows of blisters, an automatic device aligns the blisters into one middle row.

Then the defective or empty packages are rejected, the blisters expelled with the good ones are automatically reinstated and then counted, stacked and inserted into the carton together with the leaflet and booklet, where applicable.

The cartons are loaded into the magazine by hand. They are taken out one at a time, erected and inserted in a bucket conveyor belt that moves in jog mode.

They remain in this belt to the end of the filling, print-coding and closing cycle.

When errors occur such as no product or no leaflet, or barcode printing errors, the defective package is rejected at machine outfeed.

The rejected cartons are gathered inside a container fitted with a key lock that may be emptied while the machine is running.

A production-recovery operation is envisaged that consists in retrieving any good blisters that end up outside the work cycle for a number of reasons. In this case the blister packaging machine must be stationary whereas the blister conveyor belt and the cartoning machine produce cartons using the blisters taken from the retrieval magazine.

The machine's control architecture consists of two personal computers: one runs the check and

control function for the machine's functions whereas the other one runs Operator Interface function and displays alarms and archives the production setup programming parameters.

The C80/A81 is equipped with a package quality control system that is based on a series of sensors that detect any process anomalies. The defective packages are expelled into specific rejection stations.

The machine is run by various motors synchronized between one another in speed and space by an axes control system.

Absolute angular transducers detect the angular position of the main kinematisms. As such, the control logic can supply the signals necessary for the correct actuation of all the product's processing stages.

The temperatures of the heaters are controlled by heat control units fed back by thermocouple probes.

The heat control units pilot the heating elements by means of static power relays.

Specifications

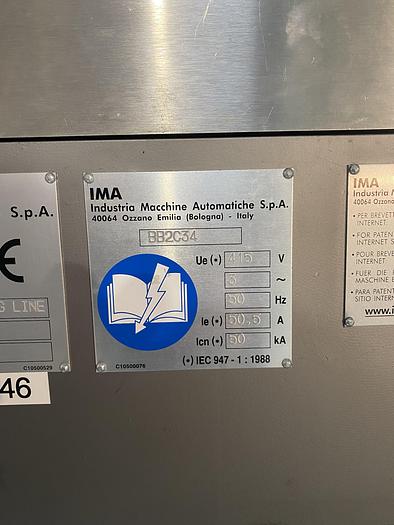

| Manufacturer | IMA |

| Model | C80/A81 |

| Year | 2008 |

| Condition | Used |

| Serial Number | SA19-20093 |

| Stock Number | GP10187 |

| Running hours | 5441 |