CAM M92 Blister Packer

Description

CAM M92 Blister Packer - Cartoner Available CAM HMM 2 at an extra cost

Key Information:

- Year 1997

- Suitable for PVC/ALU and ALU/ALU

- up to 12 blisters/stroke (up to 4 along the web and 3 across)

- Width of forming station 170mm. Maximum width of forming foil 280mm.

CAM M92 Machine Description

Designed and constructed in accordance with the requirement of the Pharmaceutical Industry and in observance of GMP standards, the M92 blister packaging machine has maintained the principal characteristics which distinguish CAM blister-packers.

SIMPLIFIED USE AND EASE OF CLEANING

The path of the web between the reel and forming material and the cutting station is as short and linear as possible giving the operator full vision and total control of all the principal functions of the machine. The above together with a careful design study which has separated the areas enclosing the mechanical movements from the areas dedicated to product handling, enable line clearance and machine cleaning upon lot change-over to be carried out with simplicity and ease. Format change-over can be carried out by the use of quick release devices, even by unskilled personnel.

FLEXABILITY/VERSATILITY

The machine can handle a wide range of forming materials, such as: PVC, PP, PVC- PVDC, PVC-PE-PVDC, ACLAR, PETG, ALU-PE, ALU-PP and lidding materials such as: ALUMINIUM, ALUMINIUM- PAPER, ALUMINIUM-PAPER-MYLAR, ALUMINIUM-PE, POLYPROPYLENE.

SOLID STRUCTURE AND MECHANICAL RELIABILITY

According to the dimensions of the product, the machine can produce up to 12 blisters/stroke (up to 4 along the web and 3 across). Web transfer is carried out by 4 mechanical grippers, the third of which acting directly on the housings, guaranteeing (with the use of any type of material) correct positioning of the formed stroke between the sealing station plates. The intermittent motion of the web is generated by a mechanical crank and slotted link device in conjunction with the motion of the feeders.

The relationship between these two movements allows the housings to be loaded even during web stand-by, giving the possibility to feed product (into the housings) during the whole cycle. Feeding throughout the complete cycle and the possibility to have up to 3 blisters across the web, allows to reduce the feeding speed of each single product lane, with obvious advantages in terms of reliability and maximum performance.

From the cutter (operating without creating crossways waste), blisters are transferred to the connecting conveyor, placed at 90° to the machine. This allows different linkage solutions with the downstream equipment including the possibility to install the blister packaging machine in an environment separate from the rest of the line

Condition: Checked, tested and running

Optional Services:

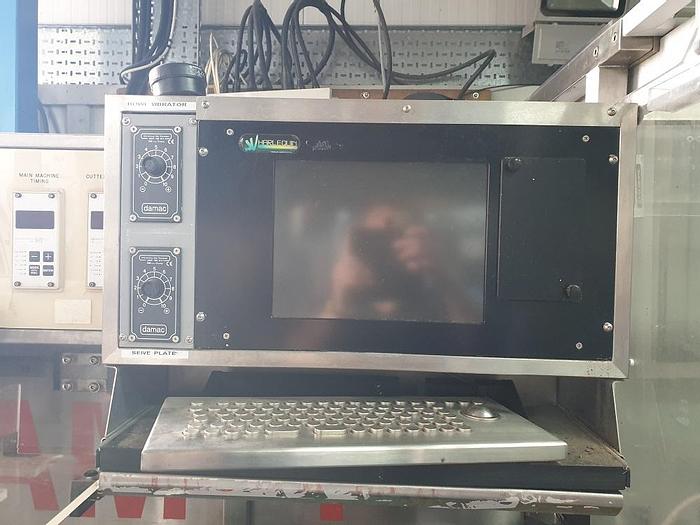

- Machine modenisation - Includes new PLC and Touch Screen HMI

- Installation and Set Up at customers facility

Specifications

| Manufacturer | CAM |

| Model | M92 |

| Year | 1997 |

| Condition | Used |

| Stock Number | VE10032 |

| Forming Station | Width of forming station 170mm. Maximum width of forming foil 280mm. |

| Blisters Per Stroke | up to 12 blisters/stroke (up to 4 along the web and 3 across) |

| Machine size | 5000mm x 1800mm x 2500mm high |